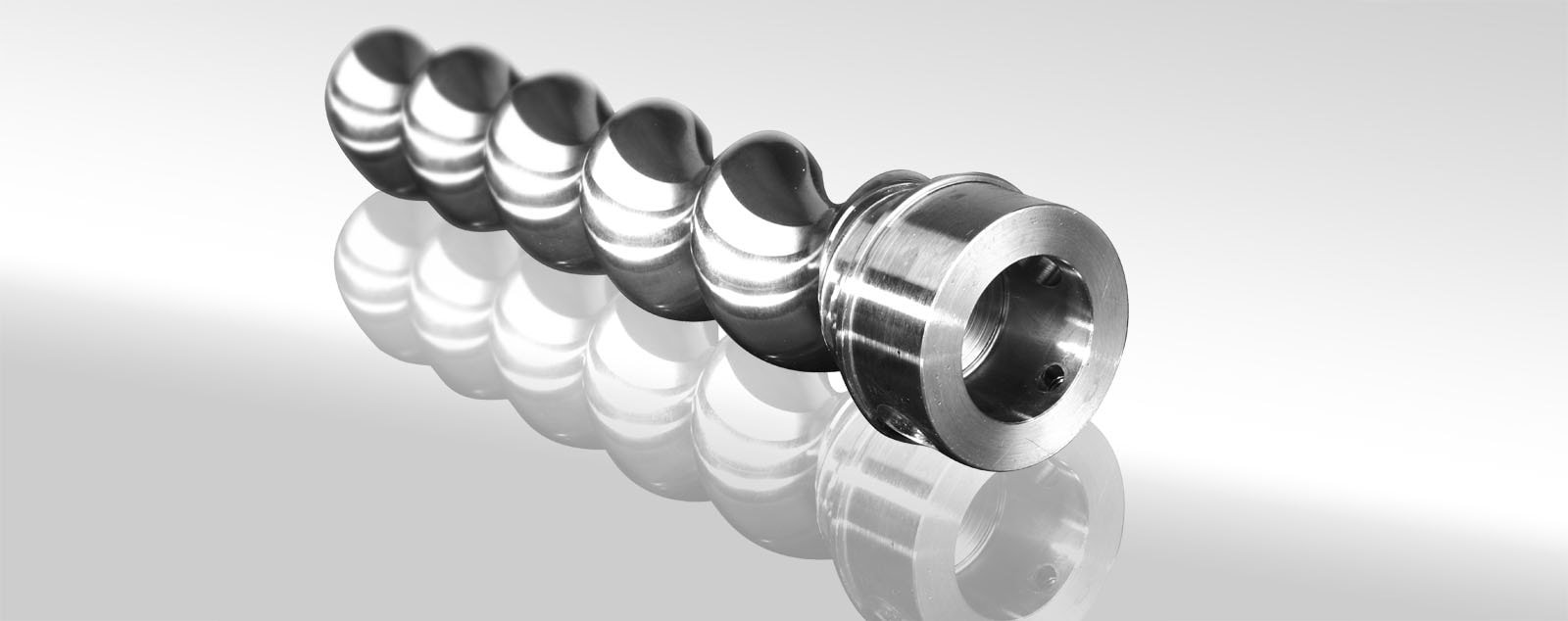

Rotors

We use the most up-to-date methods to mechanize, polish and harden our rotors. In this way we can guarantee they have the best possible surface, which ensures a long service life.

Rotors are often used at high temperatures, which is why it is neccessary to adjust the dimensions to compensate for rubber expansión.

Materials used in rotor manufacture:

- Stainless steel with and without hard chrome plating,

- Nitriding steel

We make rotors according to the requirements of your pump, adapted to your needs. The most commonly used materials in the manufacture of rotors are stainless steel and tooling steel. Also we manufacture in other materials.

We can also chrome-plate our rotors if required.

When is it necessary to change the rotor?

When the lubricated stator mounts inefficiently and there is lack of adjustment within the rotor, this is due to normal wear and tear. Then it is necessary to change the rotor.