Stators

The stators are made in molds of our own design & construction. The main property of the rubber is that it is resistant to abrasion, tear and to chemical agents. With this objective we use the appropriate rubber in each case and carry out resistance tests for specific types of abrasion.

Stators available with the TSE option. The temperature sensor must always be installed at the product entry side of the stator as the quickest temperature rise in case of dry-running will occur at this point.

The main components of the eccentric screw pump are the fixed stator (vulcanized rubber into a steel pipe) and the rotating rotor. Rotation and the design of both components create sealed chambers through which the product is transported from the suction to the delivery end of the pump.

Materials used for the manufacture of stators:

- NBR black

- NBR white

- NBR 1250

- NATURAL RUBBER

- RB (rubber compound specially resistant to abrasion with proven results)

- EPDM black

- EPDM white

- Viton, etc.

Our nbr 1250:

- Complies with the CE 1935/2004, 27/10/2004 and UE 10/2011, 14/01/2011 for contact with food.

- It also satisfies the FDA. Sec. 177.2600 Rubber articles intended for repeated use Regulation.

Our stators

Why it is important to choose the right kind of rubber

In order to give our clients the best advice for their application, we need the following information:

- A description of the type of fluid.

- Pumping temperature

- Don´t forget that during the lifetime of a pump, the type of fluid may change.

Why it is important to understand and to know about the manufacturing process of stators

Each area of application has specific demands regarding the resistance of the rubber. Decades of experience allow us to adapt the mixture of rubber to the demands of each client

Natural rubber (NR): Products to resist abrasion. Good resistance to diluted acids, detergents and alcohols. It is not appropriate for applications that come into prolonged contact with solvents, greases and hydrocarbonic oils, which cause it to swell significantly. Temperature range -30°C +80°C

Nitrile (NBR): Excellent resistance to greases and oils, as well as some hydrocarbons (gas oils). Waste water and abrasive products. Temperature range -25°C +100°C

Ethylene-Propylene (EPDM): Excellent resistance to weathering, ozone, sunlight and air. High chemical resistance to acids, alkalis, detergents, alcohols, ketones, washing bleaches, etc. Temperature range -30°C +110°C

Viton (FPM): High temperatures (up to 250ºC on tips). Hot oils, acids, alkalis. Excellent resistance to by-products of petroleum, aliphatic solvents, aromatic solvents and chlorine. Diluted acids, detergents and oxidising acids. Not appropriate for aldehydes, esters and ketones. Temperature range -25°C +250°.

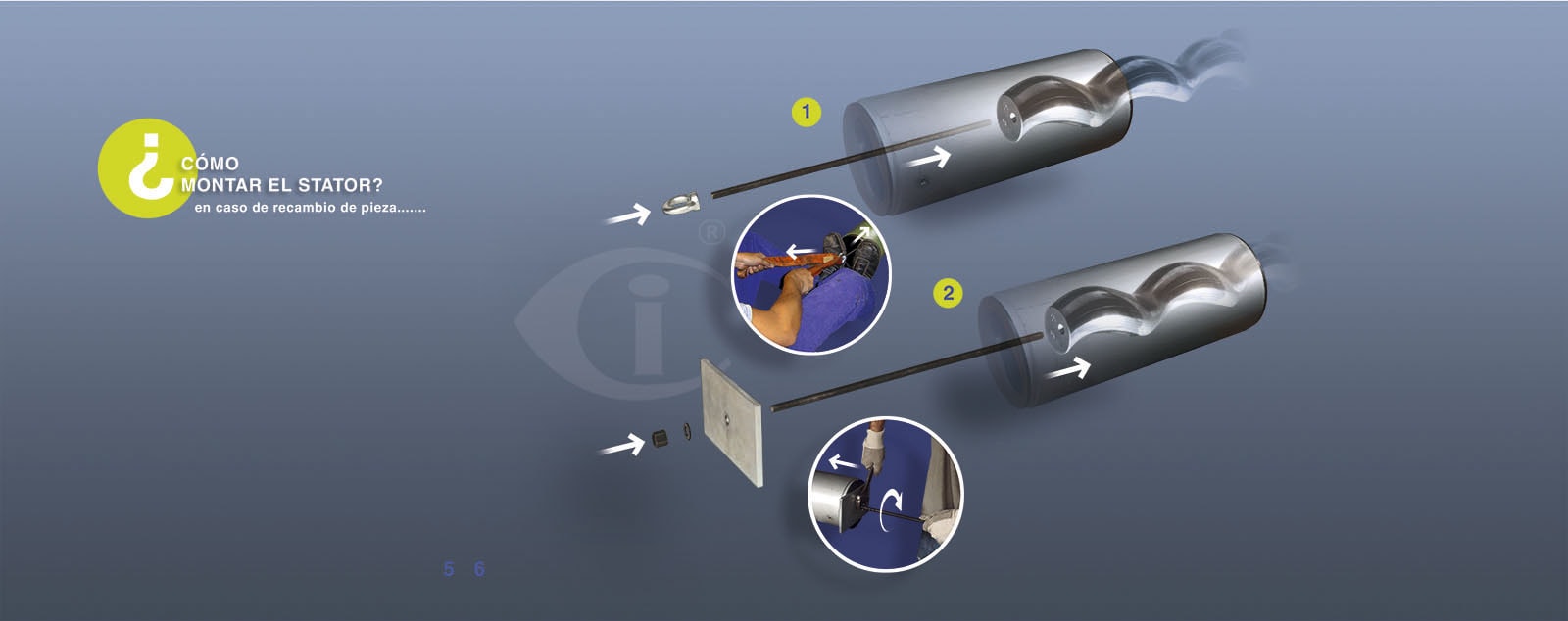

How to install the stator

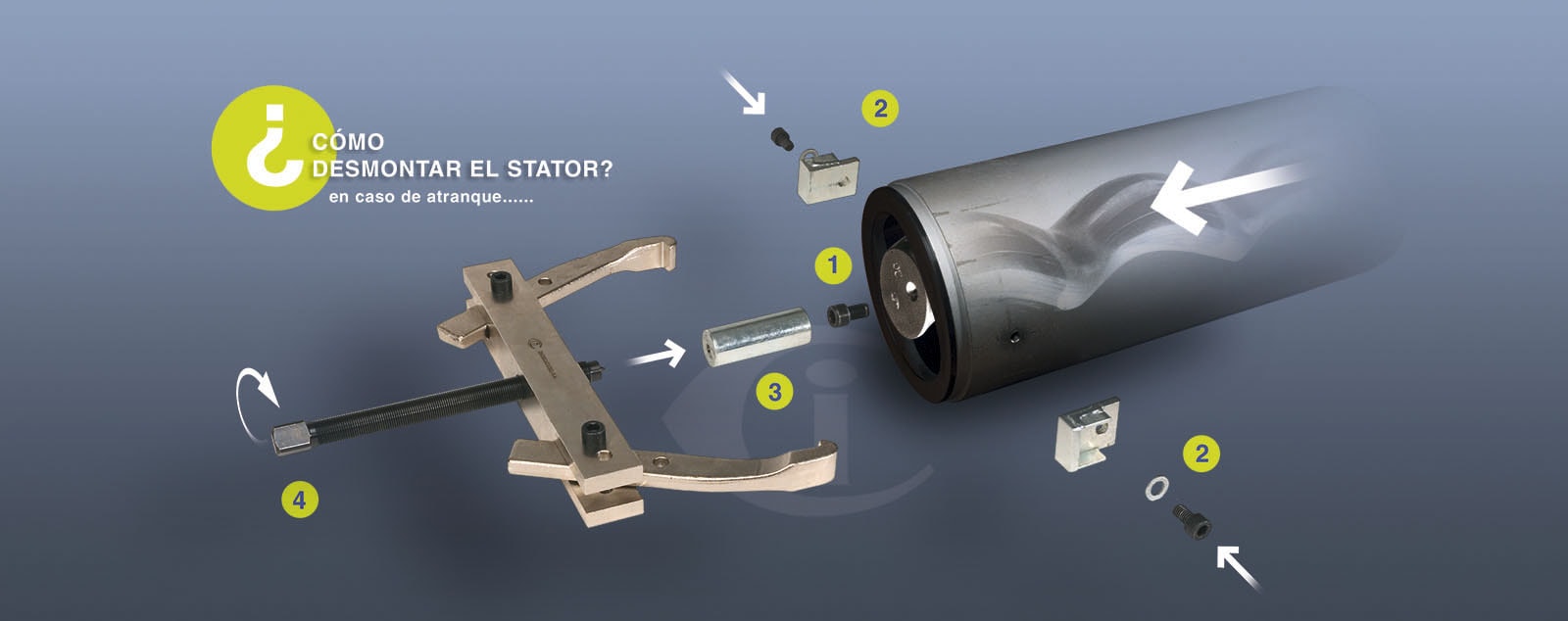

How to remove the stator in case of blockage

Advice for use

When changing a stator or after a production shutdown, it is convenient to make sure that the product is adequately pumped as soon as the machine starts because if there is any clogging, the stator can be quickly damaged.